| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : GNEE

Place of Origin : China

MOQ : 5000PCS

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 10000 Tons Per Month

Delivery Time : 30 Days

Packaging Details : Gunny Bags or Cartons And Wooden Pallet

As a crucial fastening component in the railway track system, the core function of railway spikes is to firmly anchor the rails to the sleepers or other load-bearing structures, so as to ensure that the track system has a stable structural state, good straightness and reliable safety performance. During the operation of railway trains, spikes play a decisive role. They must be able to withstand various external forces such as the weight of the train itself, the vibration and shock generated by the operation, and the stress caused by changes in ambient temperature. In view of the differences in track types and the complex and changeable working environment, railway spikes also show corresponding diversity in design and material selection.

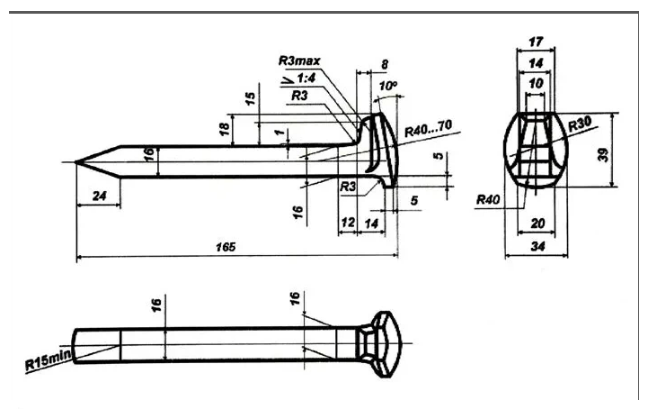

Product: Electro-galvanized rail spike

Materials: Steel Q235,35#,45#; Alloy Steel 40Cr,42CrMo,35CrMo

Grade: 3.6/4.6/4.8/5.6/5.8/6.8/8.8/10.9/12.9

Surface: Plain Oiled, Oxygen Black, Zinc Plated, Hot Dip Galvanized, Dacro coating, etc.

Material Refer to: DIN 17221,BS 970, GB, JIS, GOST, AREMA or ASTM,etc

Packing: 200lbs, 100lbs or 50lbs kegs , or Less than 25KG per double layer woven bag in fumigation free pallet , or other ways if customer request so.

MOQ: 10000 Piece/Pieces

Supply ability: 500 Ton/Tons per Month

Delivery: within 20 working days

| Features | Electro-galvanized rail spikes | Hot dipped galvanized rail spikes |

|---|---|---|

| Before galvanization | No need of clean. | Must to clean grease and dirt. |

| Techniques | Nails are galvanized with the help of an electrical current. | Nails are submerged in molten zinc. |

| Layer thickness | Thin, generally in 3 to 8 microns | About ten times the thickness of electro galvanized layer, generally in 50 to 100 microns |

| Surface appearance | Smooth and even,bright and shiny | Dull, grainy, crystallized appearance |

| Corrosion resistance | Unable to withstand continual exposure to corrosive materials such as saltwater. | Much better than electro galvanized nails due to its thick zinc layer |

| Salt spray test performance | Unable to withstand these types of surface abrasions in less than 10 hours. | The salt spray test of hot dipped galvanized nails can be reached in about 30 hours. |

| Application | Necessary for most residential purposes Not suitable to be used with acid materials, such as redwood, cedar, or treated lumber, etc. | Necessary for outdoor exposure applications Enable to be used in bad environments such as acid, corrosive, humid circumstance. |

Gnee Steel (tianjin) Co., Ltd

Since our company was founded in 2008, we have continuously increased our R&D investment and devoted ourselves to the design and manufacture of new types of railroad spikes in the past decade. Our R&D team is composed of experienced engineers who always keep pace with the international railway industry to ensure that we can provide customers with the most advanced, environmentally friendly and economical railroad spike products.

|

|

Electro Galvanized Rail Spike Q235 Rail Fasteners For High Performance Railway Operations Images |